Udlala indima ephambili ekunyuseni ukusebenza kwempompo xa ukhetha okulungileyoisethi ye-rotor yepompo. Ngokukhetha ngobulumko, unokufezekisa ukufikelelaUkusebenza okuphezulu kwe-3.87%.kwaye ujabulele ukugcinwa kwamathuba amade. Uphononongo lwakutsha nje lubonisa ukuba ii-rotors eziphuculweyo zinokunyusa ukuhamba kwempompo nge-25%, ikhuthaze inkqubela phambili yokwenyani.

Izinto eziphambili zokuThatha

- Ukukhetha uhlobo olululo lwempompo yerotor kunye noyilo kukhulisa ukusebenza kakuhle, ukuhamba, kunye nobomi bempompo kuzo zonke izicelo ezahlukeneyo.

- Ukukhetha izinto ezifanelekileyo kunye neengubo eziphambili kuphucula ukuqina kwe-rotor, kunciphisa ukugcinwa, kunye nokugcina iindleko.

- Ukuhlolwa rhoqo kunye nokukhethwa kwe-rotor ehlakaniphile kunceda ukuphepha ukuphuka, ukunciphisa ukusetyenziswa kwamandla, kunye nokwandisa ukusebenza kwempompo.

IiRotors zePump zisebenza njani kwiindidi zempompo ezahlukeneyo

I-Centrifugal Pump Rotors

Ungavula amandla okwenyani entshukumo yolwelo nge-centrifugaliirotha zokumpompa. Ezi rotors, ezihlala zibizwa ngokuba zii-impellers, zijikeleza ngokukhawuleza ukwenza amandla anamandla atyhala ulwelo ngaphandle ukusuka embindini. Esi senzo siguqula amandla oomatshini ukusuka kwinjini ukuya kumandla ekinetic, amanzi ashukumayo okanye olunye ulwelo ngempompo kunye nenkqubo yakho.

Xa ukhetha impompo ye-centrifugal, ujoyina uninzi lwamashishini kwihlabathi jikelele. Enyanisweni, iimpompo ze-centrifugal zibambe ubuninzi65% isabelokwimakethi yempompo yeshishini ngo-2021. Ubabona kuyo yonke indawo-ukusuka kumaziko okucoca amanzi ukuya kwimizi-mveliso yeekhemikhali-kuba baphatha uluhlu olubanzi lolwelo kunye namazinga okuhamba.

Ingcebiso:Ukukhetha uyilo lwe-impeller elungileyo kunokunyusa ukusebenza kwempompo yakho kunye nokuthembeka.

Ukusebenza kuyahluka ngokusekelwe kulwelo kunye nejometri yempompo. Umzekelo, iimvavanyo zibonisa ukuba ezinye iimpompo ze-centrifugal zifezekisa a3.3% intloko ephezulukunye nezisombululo ezithile xa kuthelekiswa namanzi. Nangona kunjalo, ukunciphisa isantya se-rotor kukhokelela ekunciphiseni okubonakalayo ekusebenzeni. Ukulinganisa kwamanani kuqinisekisa ezi zinto zifunyanisiweyo, zibonisa ukuba iimpompo zokuhamba kwe-axial zinokufikelela kubuchule obuphezulu86.3%, ngelixa ezinye ziyilo zingawela ngaphantsi kwe-80%. Lo mahluko ubalulekile xa ufuna ukwandisa imveliso kunye nokunciphisa ukusetyenziswa kwamandla.

Nalu ujongo olukhawulezayo kwiinkcukacha zempompo ye-centrifugal ye-rotor:

| Ukucaciswa / Ipharamitha | Inkcazo / Ixabiso |

|---|---|

| Ifomula yokunyamezelana | U = 4W/N (U kwi-oz-in, W = ethwele ubunzima bejenali, N = isantya esiphezulu senkonzo) |

| ISO Grade | Malunga ne-0.7 (ISO 1940-1) |

| API 610 Imfuneko yokulinganisa | I-Dynamic balancing ukuya kwi-ISO 1940-1 iBanga lesi-2.5 okanye ngaphezulu |

| Ukubaluleka kokulungelelanisa | Yehlisa ukungcangcazela, yonyusa ubomi bokuthwala, kwaye inciphisa ixesha lokuphumla |

Uyabona ukuba ukulinganisa okufanelekileyo kunye nokukhetha koyilo kukunceda ufezekise ukusebenza kakuhle kunye nobomi obude benkonzo. Xa utyalomali kwi-rotor yepompo ye-centrifugal efanelekileyo, uzibekela impumelelo kuyo nayiphi na isicelo.

IiRotors zePump zokufuduswa eziNgcono

Ungathembela kwi-rotors yepompo yokufuduka efanelekileyo xa ufuna ukuhamba okuzinzileyo, okuthembekileyo-nokuba ngamanzi angqingqwa okanye ancangathi. Ezi rotors zibamba umlinganiselo omiselweyo wolwelo kwaye zihamba ngepompo ngokujikeleza ngalunye. Olu luyilo lukunika ulawulo oluchanekileyo lokuhamba, lwenza ezi mpompo zilungele amashishini afana nokutya, amayeza, kunye ne-oyile kunye negesi.

Uneendlela ezininzi zoyilo lwerotor ongakhetha kuzo, nganye inamandla ahlukileyo:

| Uhlobo lwempompo | Iimpawu zoyilo lweRotor | UkuSebenza kweeNgcaciso eziSekwe kuYilo kunye nokufaneleka kweSicelo |

|---|---|---|

| I-Circumferential Piston | I-Rotors ayichukumisi okanye i-mesh; itywina eyenziwe phakathi kwestators kunye neerotors | Ukusebenza okuphezulu kwi-viscosity ephantsi; ebiza kakhulu |

| Lobe | Rotors kunxibelelwano olusondeleyo; Uqwalaselo lwelobe ezininzi | Inkulu kwiimveliso ezityebileyo; ukusebenza kancinci kwi-viscosity ephantsi |

| I-Twin-Screw | Izisonte ezimbini zisusa imveliso nge-axially; i-pulsation ephantsi | Ukuphatha kakuhle, ukunxiba okuphantsi, ixabiso eliphezulu |

Uvavanyo lwaselabhoratri lubonisa ukuba iimpompo zepiston ezijikelezileyo zikhazimla ngeencindi ezine-viscosity ephantsi, ngelixa i-lobe kunye ne-twin-screw designs zigqwesa ngezinto ezityebileyo. Ungazibona ezi mpompo zisebenza kumashishini amaninzi, ukusuka ekuhambiseni itshokolethi kumzi-mveliso weelekese ukuya ekuphatheni ioyile ekrwada kwindawo yokucokisa.

Izifundo zovavanyo kwiimpompo zepiston eziqhutywa ngumoya zityhila ukuba ukongeza ii-accumulators zoxinzelelo kunokunciphisa i-spikes yoxinzelelo ukuya kuthi ga.68%. Oku kuthetha ukusebenza okugudileyo kunye nokuncinci ukunxiba kwisixhobo sakho. Xa ukhetha i-rotor efanelekileyo yokufuduka, ufumana ulawulo, ukusebenza kakuhle, kunye noxolo lwengqondo.

Progressive Cavity Pump Rotors

Ungafikelela kwiziphumo ezimangalisayo ngeerotor zempompo eziqhubekayo, ngakumbi xa ujongene nocelomngeni okanye ufuna ukuhamba okuthambileyo, okungaguqukiyo. Ezi rotor zinemilo ye-helical ekhethekileyo ehambisa ulwelo kuluhlu lwemiqolo emincinci, etywiniweyo. Olu luyilo luphatha yonke into ukusuka kumanzi amdaka ukuya kwi-slurries engqingqwa ngokulula.

Phawula:Iimpompo zombhobho oqhubekayo sisisombululo sakho sokuya kwizicelo apho ezinye iimpompo zisokola.

Izinto ezintsha zamva nje zenze ezi rotors zanomtsalane ngakumbi. Umzekelo, uyilo lweVogelsang HiCone lukuvumela ukuba uhlengahlengise indawo yerotor, ubuyisele ucinezelo lwangaphambili kunye nokwandisa ubomi be-rotor kunye nestator ukuya kuthi ga.amaxesha amane. Unokwenza olu hlengahlengiso ngesandla okanye ngokuzenzekelayo, ugcine impompo yakho isebenza njengentsha kunye nokunciphisa ixesha lokuphumla.

Nantsi indlela i-rotors yepompo eqhubela phambili ephucula ngayo ukusebenza:

| Umba weDatha wamanani | Inkcazo / isiphumo |

|---|---|

| Uxinzelelo lokuphuma | Uyilo olutsha luyafezekiswauxinzelelo oluphezulu lokuphumakuneemodeli eziqhelekileyo. |

| Isantya sokuvuza kwe-Axial | Uyilo oluphuculweyo lubonisa ukuvuza okuncinci, ukonyusa ukusebenza kakuhle. |

| Inkqubo yoKunyanzeliswa kwangaphakathi | Ukunyanzeliswa okukhethekileyo kwandisa uxinzelelo lokukhupha kunye nokwandisa ukunyakaza kwamanzi. |

Uzuza kusetyenziso lwamandla oluphantsi, ixesha elide lenkonzo, kunye neendleko zokuyilungisa ezicuthiweyo. Ngokukhetha i-rotor yepompo ye-cavity eqhubekayo, uxhobisa inkqubo yakho yokusingatha imisebenzi enzima ngokuzithemba kunye nokusebenza kakuhle.

Iseti yePump Rotor: Izixhobo, uYilo, kunye noKhetho

Izinto eziqhelekileyo zeRotor

Unokuvula amanqanaba amatsha okusebenza ngokukhetha izixhobo ezifanelekileyo kwiseti ye-rotor yepompo. Imathiriyeli nganye izisa amandla awodwa, kwaye ukhetho lwakho lubumba ukuqina kwempompo, ukusebenza kakuhle, kunye neendleko. Ngamanzi acocekileyo, uhlala ubonaiirotors ezenziwe ngentsimbi ekhandiweyo, ialuminiyam, ubhedu, intsimbi engatyiwayo, okanye ipolymer. Ukuba uphatha amanzi ane-turbid, iipolymers zisenokungabi lolona khetho lungcono. Xa uhambisa amanzi ngezinto eziqinileyo, i-aluminiyam ayifanelekanga kangako. Ngamanzi ashushu, i-iron, ubhedu, kunye nentsimbi yokucwenga. Emanzini olwandle, ubhedu okanye intsimbi engatyiwayo iyagqama, ngelixa intsimbi etyhidiweyo isiwa. Iimpompo ze-pool kunye ne-whirlpool zidinga ii-impellers ze-polymer ukuxhathisa iziphumo ezibi ze-chlorine.

izixhobo Advanced ezifanaImixube edibeneyobatshintsha umdlalo. Ngoku unokudibanisa isinyithi kunye neepolymers ukomeleza ukuqina kunye nokunciphisa ukungqubana. Iingubo ezikhuselayo ezifana ne-tungsten carbide, esetyenziswe ngokutshiza nge-thermal okanye i-chemical vapour deposition, yenza i-rotor yakho yempompo ibe yomelele ngokuchasene ne-abrasion kunye ne-corrosion. Ezi zinto zintsha zikunceda ukuba uqhube iimpompo ixesha elide, nakwiindawo ezinzima.

Ingcebiso:Ukukhethwa kwezinto ezifanelekileyo kunokwandisa ubomi bempompo yakho kwaye kunciphise iindleko zokugcinwa.

Uphononongo lwamanani lubonisaI-E-glass fiber yeyona nto inoqoqosho kwaye isetyenziswa kakhulukwii-rotor composite. Iintsinga zekhabhoni zikunika amandla aphezulu kunye nokuqina, ngakumbi xa ukudinwa kuyinkxalabo, kodwa zibiza ngaphezulu kwaye zinokugqwala. Iifiber zeAramid zinika ubunzima obukhulu kunye nokuchasana nempembelelo, nangona zibuthathaka kuxinzelelo. Imixube yeHybrid ikuvumela ukuba ulinganise iindleko, amandla, kunye nokuqina. Idatha yokukhathala igxininisa imfuno yomgangatho ophezulu wokuvelisa kunye novavanyo lwexesha elide ukuqinisekisa ukuba iseti yakho ye-rotor yepompo ihlala ithembekile.

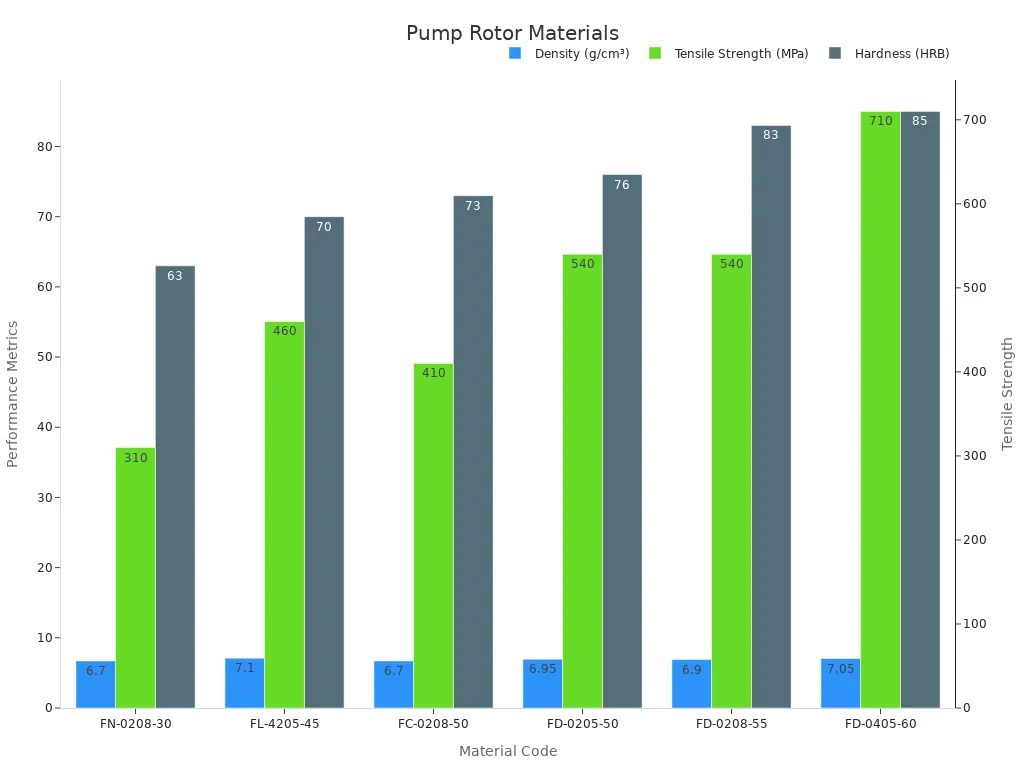

Uyawubona umahlukoukusebenza kwezinto kwitheyibhile engezantsi:

| Ikhowudi yezinto eziphathekayo | Ubuninzi (g/cm³) | Amandla Okuqina (MPa) | Ukuqina (HRB) |

|---|---|---|---|

| FN-0208-30 | 6.70 | 310 | 63 |

| FL-4205-45 | 7.10 | 460 | 70 |

| FC-0208-50 | 6.70 | 410 | 73 |

| FD-0205-50 | 6.95 | 540 | 76 |

| FD-0208-55 | 6.90 | 540 | 83 |

| FD-0405-60 | 7.05 | 710 | 85 |

Unokuthelekisa ezi mpawu ngokubonakalayo:

Iimvavanyo zamva nje zokuqina kwiirotha zegraphite zibonisa ukubaukhetho lwezinto eziphathekayo luchaphazela ixesha elingakanani i-rotor yakho yepompo ihlala. Ngokomzekelo, uhlobo olulodwa lwe-graphite rotor lulahlekelwe kuphela yi-36.9% yezinto zayo emva kwemijikelo engaphezu kwe-1,100 kwaye iqhubeke isebenza, ngelixa ezinye zahluleka ngokukhawuleza. Oku kungqina ukuba isigqibo sakho semathiriyeli sichaphazela ngokuthe ngqo ukuthembeka kwempompo.

Iimpawu zeRotor Design

Unokufezekisa impumelelo ephawulekayo kunye nokuthembeka ngokugxininisa kwiimpawu zoyilo lweseti yakho ye-rotor yepompo. Ubunjineli banamhlanje bukuzisela unyango oluphezulu lomphezulu olunjeukugquma kokutshiza okushushu kunye nokubeka umphunga wekhemikhali. Ezi ndlela zinciphisa ukungqubuzana kunye nokugqoka, okwenza i-rotors yakho ihlale ixesha elide kwaye isebenze kakuhle.

Uyaxhamla kwizithambisi ezenziwe ngobunjineli ezichanekileyo ezinezongezo ezikhethekileyo. Ezi zigcina iindawo ezihambayo zahluliwe, ukukhuhlana okuphantsi, kwaye zandisa ubomi beseti ye-rotor yakho yepompo. Izixhobo zokubala ezifana ne-Finite Element Analysis (FEA) kunye neComputational Fluid Dynamics (CFD) zikunceda ukuba ulungise i-rotor geometry kunye neendlela zokuhamba. Oku kuthetha ukuba amandla amancinci achithwayo kunye nolwelo oluninzi olushukunyiswa rhoqo ngokujikeleza.

- Ukunyamezelwa kokuvelisa okuqinileyo kunciphisa umva kunye nokuvuza, ukonyusa ukusebenza kakuhle.

- Iinkqubo zolungelelwaniso lweLaser ziqinisekisa ukuba i-shaft yakho ijikeleza ngokugqibeleleyo, ikhusela uxinzelelo kunye nokusilela kwangoko.

- Uyilo lweRotor kunye negumbi lidala ukuhamba okugudileyo, okuzinzileyo, okulungele ulwelo olubuthathaka okanye olungqingqwa.

- Iinzwa zexesha langempela kunye nokufunda koomatshini ziqikelela iimfuno zokugcinwa, ukunciphisa ixesha kunye nokugcina imali.

Phawula:Ukusebenza koxinzelelo oluphantsi kwiimpompo ze-rotor kunokukugcina ukuya kwi-30% kumandla kwaye ukwandise ubomi bezixhobo nge-20-25%.

Ijiyometri yerotor entsha ikwabonelela ngophuculo olunokulinganiswa. Umzekelo,ukwandisa i-blade pitch kunye nokuqinaiphucula ukuchaneka kwe-flowmeter. Ukulungelelanisa i-hub-to-tip ratios kunye ne-blade angles kunciphisa iimpazamo kwaye kugcina ukusebenza kuzinzileyo. Ukusebenzisa i-algorithms yemfuzo ukucokisa iimilo zepropeller kunqumle impazamo engeyo-linearity ngesiqingatha kwaye kwehliswe ubuncinci besantya esilinganisekayo sokuhamba. Le nkqubela phambili yoyilo ikunceda ukuba ufumane okuninzi kwiseti yerotor yakho yempompo.

Ukulinganisa kunye novavanyo lweprototype luqinisekisa ezi zibonelelo. Umzekelo, uyilo lwe-twin-rotor luphumelele ai-coefficient yamandla ngaphezulu kwe-0.44kunye nophuculo lokuguqulwa kwamandla nge-9% ngaphezu koyilo oluqhelekileyo. Ezi ziphumo zibonisa ukuba ukhetho loyilo oluhlakaniphile lukhokelela kwiinzuzo zehlabathi lokwenyani.

Ukukhetha iSeti yePump Rotor yasekunene

Ubambe amandla okuguqula indlela yokusebenza kwenkqubo yakho ngokukhetha iseti yerotor yempompo efanelekileyo. Qala ngokuqwalasela ukusebenza kakuhle kunye nokusetyenziswa kwamandla. Iiseti ezisebenza kakuhle kakhulu zinokunciphisa iindleko zakho zokusebenza kunye nefuthe lokusingqongileyo. Umzekelo, iiseti zemagnethi yepom yepom esisigxina ziyafikelelaukuya kuthi ga kwi-94%.-Ipesenti ze-10-12 zamanqaku aphezulu kuneenjini eziqhelekileyo. Oku kunokukongela ukuya kuthi ga kwi-21% kusetyenziso lwamandla kwaye kunciphise ukukhutshwa kweCO2 ngonyaka ngaphezulu kweetoni ezingama-32 kwezinye izicelo.

Xa ukhetha iseti ye-rotor yepompo, jonga ezi ndlela zibalulekileyo:

- Ukusebenza kakuhle kunye nokonga amandla

- Ukulawulwa kokuqukuqela ukuziqhelanisa nokutshintsha iimfuno

- Ukuqina kunye nokumelana nokunxiba ubomi obude

- Ingxolo ephantsi yendawo yokusebenzela ekhuselekileyo, ekhululekile

- Uyilo oluqinileyo kunye nokufakwa lula

Kufuneka kwakhonasebenzisa impompo yakho ngaphezulu kwe-60% yeNdawo yayo yokuSebenza ngokuGqwesileyo (BEP)ukuphepha ukungcangcazela kunye nokungazinzi. Gcina i-rotor deflection iphantsi ukukhusela amatywina kunye nokuthintela umonakalo. Ipompo eqinile kunye nezakhiwo ze-baseplate zinciphisa ukungahambi kakuhle kunye noxinzelelo. Bukela iziphumo eziguquguqukayo ezifana ne-resonance, ngakumbi ngeepompo eziguquguqukayo zesantya. Jonga rhoqo ukunxiba, njengoko ukunyuswa kokunyuka kunokunciphisa ukusebenza kakuhle. Izenzo ezilungileyo zokufakela-iziseko eziqinileyo, ulungelelwaniso olufanelekileyo, kunye namandla amancinci okubhobhoza-nceda iseti yakho ye-rotor yepompo isebenze ngokusemandleni ayo.

Impembelelo:Lonke ukhetho olulumkileyo olwenzayo ekukhetheni nasekugcineni iseti yepom yerotor ikusondeza ekusebenzeni okuphezulu kunye nempumelelo ehlala ihleli.

I-Case studies ingqina ixabiso lotyalo-mali lwakho. Emigodini, ukutshintshela kwiiseti ze-rotor zempompo ezikumgangatho ophezulu zonga amandla aphantse abe ngama-42,000 kWh nyaka ngamnye kwaye zizihlawulele ngokwazo kwisithuba esingaphantsi kweminyaka emibini. Kwiinkqubo zikamasipala, olu hlaziyo lulingana nokongiwa kwamandla okutshintsha iibulb ze-incandescent ezingaphezu kwama-300 ngee-LED. Unokufezekisa iziphumo ezifanayo ngokugxininisa kwi-rotor yepompo echanekileyo elungiselelwe iimfuno zakho.

Uqhuba impumelelo yepompo ngokukhetha i-rotor efanelekileyo kwaye uyigcine kwindawo ephezulu.

- Ukuhlolwa rhoqo ngedatha ehlakaniphile kukunceda ubone iingxaki kwangethuba kwaye uphephe ukonakaliswa kweendleko.

- Qaphelaukhetho lwe-rotorkwandisa ukusebenza kakuhle kwaye konga imali ngokuhamba kwexesha.

- Iinzuzo ezincinci ekusebenzeni kakuhlekunokukhokelela kugcino olukhulu kunye nexesha elincinci lokuphumla.

FAQ

Kwenzeka ntoni ukuba ungayihoyi ukugcinwa kwe-rotor?

Usengozini yokungaphumeleli kwempompo kunye nokulungiswa kweendleko. Ukuhlolwa rhoqo kugcina inkqubo yakho yomelele kwaye ithembekile. Hlala usebenza kwaye ubukele impompo yakho ikhula.

Wazi njani ukuba utshintshe i-rotor yempompo?

Uqaphela ingxolo engaqhelekanga, ukuhamba okuphantsi, okanye ukuvuza. Thembela kwithuku lakho. Isenzo esikhawulezileyo sikunceda ukuba uphephe iingxaki ezinkulu kwaye ugcine impompo yakho isebenza kakuhle.

Ngaba unokuphucula i-rotor yakho yepompo ukuze usebenze ngcono?

Ngokuqinisekileyo! Unokukhetha izixhobo eziphambili okanye uyilo olutsha. Ukuphucula kwandisa ukusebenza kakuhle kwaye kwandisa ubomi bempompo yakho. Yonke impucuko ikusondeza kwimpumelelo.

Ixesha lokuposa: Jul-09-2025