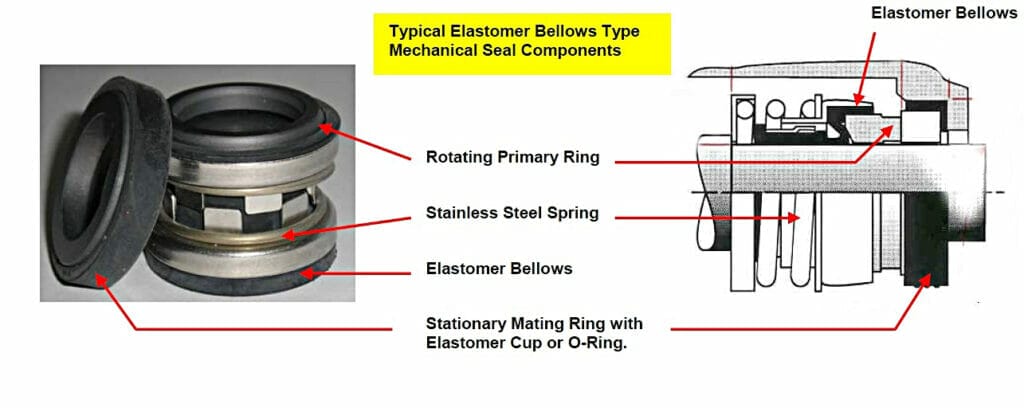

Uyilo kunye nomsebenzi wezitywino zoomatshini ziyinkimbinkimbi, ziqulathe izinto eziphambili ezininzi. Zenziwe ngee-seal faces, ii-elastomers, izitywino zesibini, kunye nehardware, nganye ineempawu kunye neenjongo zayo ezizodwa.

Iindawo eziphambili zesitywino soomatshini ziquka:

- Ubuso obujikelezayo (Iringi eyintloko):Le yinxalenye yesitywina soomatshini esijikeleza kunye nomngxuma. Ihlala inobuso obuqinileyo, obungagugiyo obenziwe ngezinto ezifana nekhabhoni, iseramikhi, okanye i-tungsten carbide.

- Ubuso obungashukumiyo (Isihlalo okanye iRingi yesibini):Ubuso obungashukumiyo buhlala buqinile kwaye abujikelezi. Ngokwesiqhelo benziwe ngezinto ezithambileyo ezihambelana nobuso obujikelezayo, nto leyo eyenza ujongano lwetywina. Izinto eziqhelekileyo ziquka i-ceramic, i-silicon carbide, kunye nee-elastomers ezahlukeneyo.

- Ii-Elastomers:Izinto ezisetyenziswa kwi-elastomeric, ezifana nee-O-rings kunye nee-gaskets, zisetyenziselwa ukubonelela ngetywina eliguquguqukayo nelikhuselekileyo phakathi kwendlu engashukumiyo kunye ne-shaft ejikelezayo.

- Izinto zokutywina zesibini:Ezi ziquka ii-O-rings zesibini, ii-V-rings, okanye ezinye izinto zokuvala ezinceda ekuthinteleni ukungcola kwangaphandle ukuba kungangeni kwindawo yokuvala.

- Iinxalenye zeSinyithi:Izinto ezahlukeneyo zesinyithi, ezifana ne-casing yesinyithi okanye i-drive band, zibamba i-mechanical seal kunye kwaye ziyiqinise kwizixhobo.

Ubuso besitywino soomatshini

- Ubuso besitywino esijikelezayo: Isangqa esiphambili, okanye ubuso besitywina esijikelezayo, sihamba kunye nenxalenye yomatshini ojikelezayo, ngokuqhelekileyo ishaft. Le sangqa idla ngokwenziwa ngezinto eziqinileyo nezihlala ixesha elide ezifana ne-silicon carbide okanye i-tungsten carbide. Uyilo lwesangqa esiphambili luqinisekisa ukuba inokugcina amandla okusebenza kunye nokungqubana okubangelwa ngexesha lokusebenza komatshini ngaphandle kokuguquka okanye ukuguguleka okugqithisileyo.

- Ubuso obungashukumiyo bophawu: Ngokungafaniyo neringi yokuqala, iringi yokudibana ihlala imile. Yenzelwe ukwenza isibini sokuvala kunye neringi yokuqala. Nangona imile, yenzelwe ukwamkela intshukumo yeringi yokuqala ngelixa igcina itywina eliqinileyo. Iringi yokudibana idla ngokwenziwa ngezinto ezifana nekhabhoni, iseramikhi, okanye i-silicon carbide.

Ii-Elastomers (ii-O-rings okanye ii-bellows)

Ezi zinto, ezidla ngokuba zii-O-rings okanye ii-bellows, zinceda ukubonelela ngokuthamba okufunekayo ukugcina isitywino phakathi kwendibano yesitywino soomatshini kunye nomngxuma okanye indawo yokuhlala yomatshini. Ziyamkela ukungalingani okuncinci kweshaft kunye nokungcangcazela ngaphandle kokuphazamisa ukuthembeka kwesitywino. Ukukhethwa kwezinto ze-elastomer kuxhomekeke kwizinto ezahlukeneyo, kubandakanya ubushushu, uxinzelelo, kunye nohlobo lolwelo oluvalwayo.

Izitywina zeSibini

Izitywino zesibini zizinto ezibonelela ngendawo yokutywina engashukumiyo ngaphakathi kwendibano yesitywino soomatshini. Ziyandisa ukusebenza kunye nokuthembeka kwesitywino, ingakumbi kwiimeko eziguqukayo.

Izixhobo zekhompyutha

- Imithombo: Izipringi zibonelela ngomthwalo ofunekayo kwiindawo zokutywina, ziqinisekisa unxibelelwano oluqhubekayo phakathi kwazo naphantsi kweemeko zokusebenza ezahlukeneyo. Olu nxibelelwano oluqhubekayo luqinisekisa utywino oluthembekileyo nolusebenzayo kulo lonke ixesha lokusebenza komatshini.

- Izigcini: Izigcini zibamba izinto ezahlukeneyo zesitywino kunye. Zigcina ulungelelwaniso oluchanekileyo kunye nendawo yendibano yesitywino, ziqinisekisa ukusebenza kakuhle.

- Iipleyiti ze-gland: Iipleyiti ze-gland zisetyenziselwa ukufaka isitywino kumatshini. Zixhasa ukuhlanganiswa kwesitywino, zisigcina sikhuselekile endaweni yaso.

- Seta izikrufu: Izikrufu ezibekweyo zizinto ezincinci, ezinemisonto ezisetyenziselwa ukubopha indibano yesitywina soomatshini kwi-shaft. Ziqinisekisa ukuba isitywina sigcina indawo yaso ngexesha lokusebenza, zithintela ukufuduka okunokwenzeka okunokuphazamisa ukusebenza kwesitywina.

Ukuququmbela

Icandelo ngalinye lesitywino soomatshini lidlala indima ebalulekileyo ekutywinweni okusebenzayo koomatshini bemizi-mveliso. Ngokuqonda umsebenzi kunye nokubaluleka kwezi nxalenye, umntu unokuyiqonda indlela enzima kunye nokuchaneka okufunekayo ekuyileni nasekugcineni izitywino zoomatshini ezisebenzayo.

Ixesha lokuthumela: Disemba-22-2023