IIMEKO ZOKUSEBENZA:

UBUSHUSHU: -20 ℃ ukuya ku +210 ℃

UXINEZELO: ≦ 2.5MPa

Isantya: ≦15M/S

IZINTO EZIBALULEKILEYO:

IRINGE YESITALI: IMOTO/ SIC/ TC

IRINGE EROTARY: IMOTO/ SIC/ TC

ISITYWINO SESIBINI: VITON/ EPDM/ AFLAS/ KALREZ

IINGXALENYE ZENTWASAHLOBO NESIMBI: SS/ HC

ISICELO:

AMANZI ACOCEKILEYO,

AMANZI E-WEWAGE,

IOYILE NEZINYE IZINTO EZINGENAMDLALO NGOKUPHELELEYO.

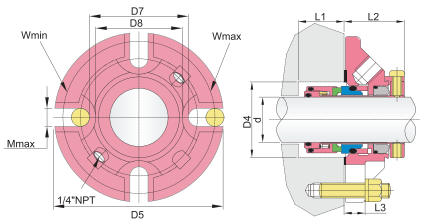

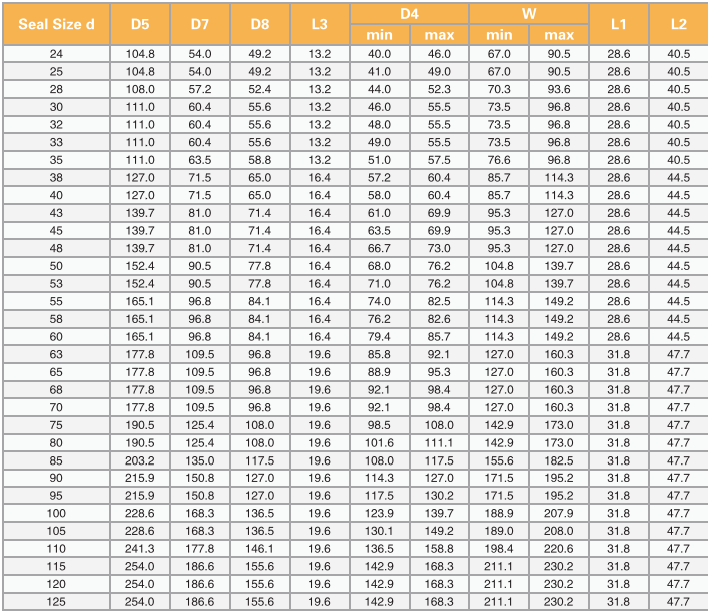

Iphepha ledatha le-WCURC lobukhulu (mm)

Iingenelo zeCartridge Type Mechanical Seals

Iingenelo eziphambili zokukhetha izitywino zekhatriji kwinkqubo yakho yokutywina iipompo ziquka:

- Ukufakela okulula / okulula (Akukho ngcali ifunekayo)

- Ukhuseleko oluphezulu olusebenzayo ngenxa yesitywina esihlanganisiweyo esinolungiselelo lwe-axial. Susa iimpazamo zokulinganisa.

- Kwasusa amathuba okuba kubekho ukungasebenzi kakuhle kwe-axial kunye neengxaki zokusebenza kwetywina ezibangelwa yiyo

- Ukuthintela ukungena kokungcola okanye ukonakalisa ubuso besitywino

- Iindleko zokufakela ezincitshisiweyo ngexesha lokufaka elincitshisiweyo = Amaxesha okungasebenzi ancitshisiweyo ngexesha lokulungisa

- Inokwenzeka yokunciphisa izinga lokuqhekeka kwepompo ukuze kutshintshwe isitywino

- Iiyunithi zekhatriji zinokulungiswa lula

- Ukukhuselwa kwe-shaft/shaft sleeve yomthengi

- Akukho mfuneko yokuba iishafti ezenziwe ngokwezifiso zisebenze isitywino esilinganayo ngenxa yesingxobo sangaphakathi seshafti sekhatriji yesitywino.